Rosahl membrane selection

Rosahl membranes are low power dehumidifiers for protecting equipment from moisture damage and condensation. They are for air drying steady-state cabinets and enclosures up to 4m³ or 140 cu ft. Steady-state means at a constant temperature using an airtight enclosure to minimise moisture ingress.

Where cabinets are opened, consider the time needed to reduce the humidity to the set-point. If needed, select a larger membrane to reduce the drying period. The expectation is that cabinets using Rosahl dehumidifiers will remain closed for most of the time. Enclosures larger than 4m³, may need more than one Rosahl membrane.

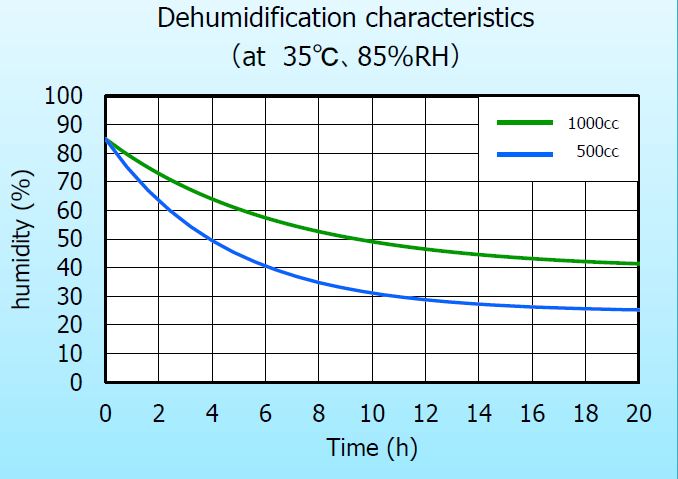

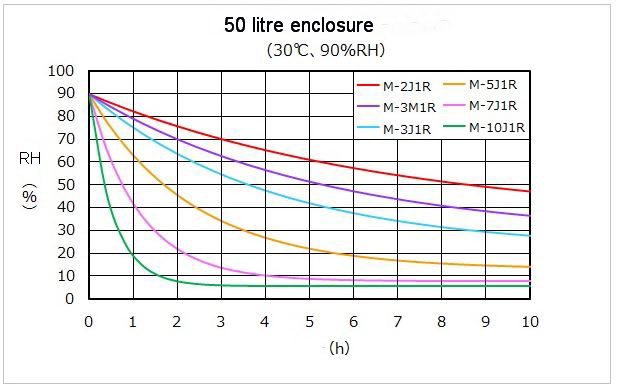

The precise drying time will depend on several variables, like starting and target humidity, air temperature, volume, and leakage area. The following membrane selection tables give an indication of drying times. We recommend undertaking your own tests.

Economy of selection

For different enclosure sizes, we recommend different models of Rosahl. If the initial drying time is not critical, or the enclosure remains closed for most time, or you have a lower starting humidity, it may be possible to use a smaller membrane.

It is also important to consider the volume of air inside the enclosure rather than the external dimension. For example, if your enclosure is 50% full by volume of non-porous material, then the space volume for dehumidifying is smaller. Finally, try and design your application to ensure you are dehumidifying the smallest volume possible.

Half-life

Rosahl has a half-life of about five years when operated 24/7 at an average operating temperature of 18°C. This means that after five years, a membrane has 50% of the capacity of a new membrane. Selecting a larger membrane for the application will give a longer effective operating life.

The half-life falls if the average annual operating temperatures is above 18°C. It is longer at lower average annual operating temperatures and when operating for shorter periods of time. For unpowered membranes or when in storage, the operating life is unaffected.

Selection

As many factors that affect membrane selection vary over time, information here is for guidance. All drying curves assume a constant temperature and the use of an airtight enclosure. For example, if the contents of the enclosure are porous, drying times will be longer than indicated in the drying curves below. When cooling the enclosure or there are large changes in ambient temperature, calculate the membrane based on its dehumidifying capacity (grams/hour) given in the specification tables. Where possible, dehumidify before the cooling process starts. See notes on humidity

ROSAHL’s dehumidifying capacity (cabinet internal humidity) is determined from the volume of air in the cabinet and its humidity. From the table below, select a suitable model for the volume and target humidity. For example, if your cabinet has a volume of 0.5m³ and your target humidity is 50% then select the M-5J1R or MDL-5 membrane. This table allows for an ambient humidity of up to 90%.

Selection of membrane by volume and target humidity

| For <90% RH ambient | Target humidity 30% RH | Target humidity 50% RH | Target humidity 75% RH |

|

| Membrane selection | ||||

| PD4, PD5 | 0.25 l | 0.5 l | 1 l | |

| PD2, PD3, RD3, RD4 | 0.5 l | 1 l | 2 l | |

| RS1, RS2 | 1.25 l | 2.5 l | 5 l | |

| M-1J1R | 30 l | 65 l | 125 l | |

| M-2J1R | 60 l | 125 l | 250 l | |

| M-3M1R | 90 l | 180 l | 350 l | |

| M-3J1R & MDL-3 | 0.125 m³ | 0.250 m³ | 0.5 m³ | |

| M-5J1R & MDL-5 | 0.25 m³ | 0.5 m³ | 1 m³ | |

| M-7J1R & MDL-7 | 0.5 m³ | 1 m³ | 2 m³ | |

| M-10J1R | 1 m³ | 2 m³ | 4 m³ |

Drying time curves

The following curves indicate drying performance under defined conditions. The characteristics of the graphs will vary depending on the material in the container and the degree of air-tightness/leakage. If the container contains absorbent material, the membrane induces release of moisture from the material, which may slow dehumidification inside the container. The dehumidifying capacity of the membrane varies according to the absolute water amount inside the container. Changes in the ambient humidity may also affect the performance, and the curves are provided for guidance only.

Important user notes:

Refer to the user manuals in the documentation section of this site. In addition, please note the following points to help you use Rosahl correctly. If you are in any doubt about the suitability of Rosahl for your application, please contact us.

– Rosahl is not intended as a domestic product and is for installation by a qualified person

– Rosahl is for dehumidifying steady-state (sealed) enclosures or cabinets

– The membranes have a half-life of five years’ operating 24/7 at an average annual operating temperature of 18°C. Half-life declines at higher average operating temperatures. When unpowered, the operating life is unaffected by temperature

– You can increase the effective operating life by over-sizing the membrane, using a humidity controller, or operating at lower average temperature

– The device will be effective from -20° to +50°C (the manufacturer has tested it for storage between -40° C up to +80°C).

– When unpowered, the membranes do not provide a barrier to moisture from entering the enclosure.

– The devices require a power supply of 3V DC with constant current-limiting protection. Some fold-back type PSUs are not suitable. All hiccup mode PSUs are unsuitable.

– Power consumption figures are the expected daily average based on our evaluation

– Do not use silicone rubber sealants unless vulcanised by heat curing, as they may damage membrane and performance.

Refer to the FAQ section or contact us for specific applications. For further information see Membrane Selection

Go here for typical Rosahl user guide

Rosahl

micro-dehumidifier

micro-Entfeuchter

micro-déshumidificateur

micro-deshumidificador

Website Usage

Westside International Ltd

Registered in England

Registration No. 4018025

VAT No. 768327395

EIN 98-1234498