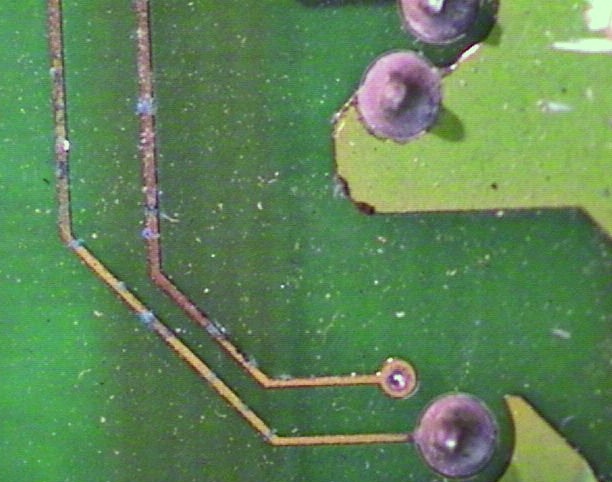

In an article on contamination and the effects on printed circuit board reliability, ERA Technology identified several leading causes. The main causes of damage to pcbs were du/e to moisture; applied voltage, and ionic contamination.

According to the article, pcbs can suffer from a variety of problems due to surface contamination from electrically conducting materials. Combined with moisture, this results in a lowering of resistance between tracks and pads leading to corrosion of metals. It can also result in the formation of metal filaments growing between pads or tracks on rigid or flexible circuits. Also, between oppositely charged metal terminations of components, or between the pins of connectors.

Damage to pcbs

Their conclusion was that the ideal environment is constant temperature, and a relative humidity of 40 – 50 %. Above 50% RH there is increasing likelihood of water condensing on the surface of circuitry when the air temperature falls.

Where the pcb surface is at a lower temperature than the ambient air, this cools the air adjacent to the surface. The results in an increase in the local relative humidity. Condensation occurs when the temperature falls to the dewpoint temperature and relative humidity reaches 100%, resulting in and water condensing. Another cause of damage can be the presence of water vapour in its gaseous form.

Simple moisture reduction precautions for vulnerable applications or locations will save significant downtime and costs of replacement. Rosahl’s unique solid-state ionic membrane dehumidifier provides a compact, maintenance free air-drying solution. It provides protection against moisture in steady environments, reducing the risk of damage and failure.