In fact, yes, they do. More than that, Rosahl membranes offer a long-term solution to filament drying without heat or maintenance. Of course, knowing a little more will deliver the best balance of cost and performance. Keep reading to find out more.

Rosahl dehumidifiers use an ionic membrane for drying enclosures from under one litre to over 2m³. What is more, they are prevalent in industrial and commercial drying applications to protect electronics, photonics, artefacts and more.

For filament drying, the important points are that Rosahl membranes are small, cheap to run, and maintenance free. As a result, they will work with filament storage boxes and with continuous spooler feed boxes.

Markedly, their steady-state power consumption is around 3W, so a typical membrane has an average annual running cost of under £8 ($10 or €10) and a service life of up to five years. Just as important, the low running cost and negligible heat generation mean it will operate 24/7 without damaging the filaments.

Two jobs

Rosahl is an active dehumidifier. Firstly, it dries the air in the storage or feeder box, then it draws moisture out of the filament. Over time, this is very effective and when correctly sized can maintain relative humidity levels of 15% or lower. See the membrane selection table below on sizing the membrane for your target humidity.

If you are using a heated dry box, it will remove moisture from the membrane much faster. Then transfer the filament to a storage or feeder box where the Rosahl membrane will keep it dry and reduce the electricity used.

How does Rosahl work?

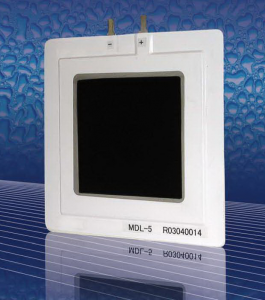

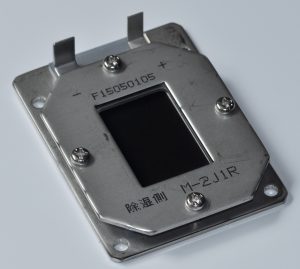

Rosahl membranes comprise a proton-conductive solid polymer electrolyte (SPE) with porous electrodes. On applying 3 Volts D.C. to the terminals, the anode attracts moisture where it dissociates into hydrogen ions and oxygen. The hydrogen ions (not hydrogen gas) migrate through the membrane and once outside the enclosure they react with air to form water vapour.

For this to happen, it is necessary to make a hole in the enclosure through which they can expel the unwanted vapour/gas. The preferred location is vertical mounting on one of the enclosure sides.

Rosahl membranes can reduce the relative humidity (RH) to 20% or lower depending on the size of enclosure and membrane selected. More than that, over-sizing the membrane for a given volume reduces the initial drying time and further lowers the level of RH reached. It can also extend the effective operating life of the membrane.

The external humidity and the degree of sealing against moisture ingress influence the drying performance. Nevertheless, the better the sealing the lower the humidity achievable and the lower the running cost. Equally, it is clear there will always be a small leakage and that does not present a problem.

Moreover, when operating, the density of oxygen in the container increases as the water molecules dissociate into hydrogen ions and oxygen, and oxygen remains in the container. Due to normal leakage and the occasional opening of the container, the oxygen density is typically 2 to 3% above background levels.

Half-life

Rosahl has a half-life of about five years when operated 24/7 at an average annual operating temperature of 18°C. Accordingly, a membrane operating for five years has 50% of the capacity of a new membrane.

Because of the polymer membrane being porous, when un-powered it will allow moist air to re-enter the enclosure. Hence, users should either leave the power connected or install a hygrostat.

Membrane selection

For different enclosure sizes, select the correct Rosahl from the table in the selection information of the website, or the short form table below. The enclosure can be as large as needed. When using larger storage cases of 500 to 1000 litres, an internal circulatory fan will hasten drying performance, but is not necessary otherwise.

| <70% RH Ambient | 25% Target Humidity | 40% Target Humidity | Prices from April 2022 |

|---|---|---|---|

| Membrane Selection | |||

| RS Series | 1.25 litres | 2.5 litres | £32 $41 €37 |

| M-1J1R | 30 litres | 65 litres | £58 $78 €68 |

| M-2J1R | 60 litres | 125 litres | £71 $92 €83 |

| M-3M1R | 90 litres | 180 litres | £92 $121 €108 |

| M-3J1R & MDL-3 | 125 litres | 250 litres | £120 $156 €139 |

| M-5J1R & MDL-5 | 250 litres | 500 litres | £195 $253 €226 |

Table 1. Membrane selection by target humidity

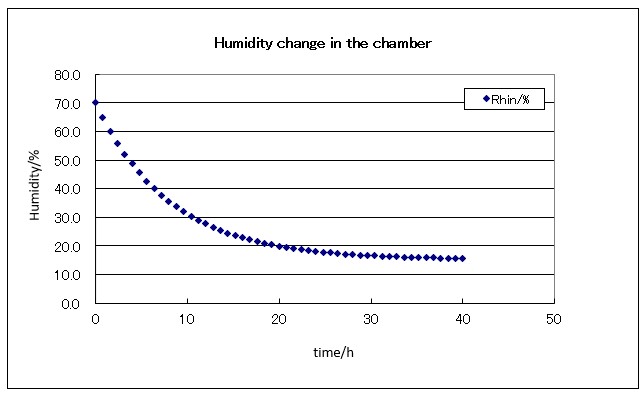

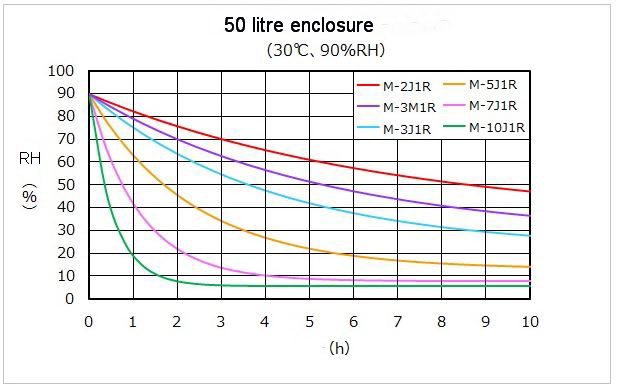

Drying time curves

Below we consider enclosures of 50 and 125 litres. For ease of selection, typical drying time curves for Rosahl membranes are available. These give users and designers a clue of what drying performance to expect. Changes in the ambient humidity will affect the performance, and the curves are for guidance only. The curves will vary depending on the material in the container and the degree of air tightness/leakage. If new printer filaments have a high moisture content, initial drying make take longer than indicated.

Drying simulation for a 125-litre enclosure in a 70% RH 18°C ambient using a size 3J membrane and leakage area of less than 3.4 cm²

The curves will vary depending on the material in the container and the degree of air tightness/leakage.

Control

The choice of membrane control depends on the user preference. The membrane will operate 24/7 without an external humidity controller (hygrostat). The current draw from the Rosahl membrane is proportional to the humidity level. This means that as the humidity falls, the current falls automatically.

When using a hygrostat for precise humidity control it is preferable to switch the mains power to the power supply feeding the dehumidifier. Use a hygrostat when drying natural materials to avoid damaging them.

It is important to select a suitable power supply that manages the inrush current without tripping. The output voltage to the membrane must be in the range 3 to 3.3V DC

Advantages of using Rosahl membrane dehumidifiers

Rosahl membranes are one of many potential answers to filament drying and unquestionably offer many benefits over traditional solutions.

| Features | Benefits |

|---|---|

| Made by Mitsubishi Electric Corporation | Globally respected manufacturer of high-quality electrical products |

| Established product | Many millions of applications over 12 years |

| Compact | Fits almost any enclosure from <1 litre to 4 m³ |

| No moving parts | Silent in operation Vibration free Nothing to wear out |

| Solid state membrane | Low energy footprint High reliability Long operating life |

| Long operating life | Suitable for remote locations Idea for hard to service equipment |

| Lower operating cost | Involves no liquid water Maintenance free No drain required No cleaning Lower total cost of ownership (TCO) |

Rosahl membrane dehumidifiers are available from Westside International Ltd in the UK from where we ship worldwide. See the Rosahl website for more information or email us of you have an application question

Helpful Rosahl links

Printer friendly version of this article (PDF download)

Documentation and Installation guides

Summary of Rosahl product range

Important membrane selection information